Damage detection using ML

Service-life prediction and damage detection for a centenary steel bridge -Vänersborg

Steel as a construction material emerged in the late 19th century. The early riveted bridges and the welded structures built decades later are reaching 100 years of service. They have proven high resistance and durability, but degradation processes such as corrosion and fatigue take their toll. Theoretical code-based assessments often show insufficient service life of these bridges when it comes to fatigue. If corrosion damages are detected, the cost of repairs and strengthening tends to accelerate.

One example is the bascule railway bridge in Vänersborg. It opened for traffic in 1916 and has carried freight, intercity and commuter trains for over a hundred years. Theoretical assessments have indicated fatigue, and inspections have identified damages such as corrosion and cracking. Repair and strengthening actions have been recurrent over the years.

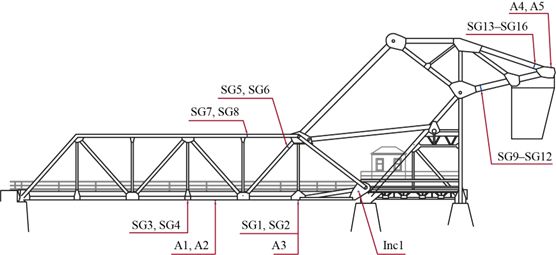

IoTBridge was engaged in 2021 for continuous sensor-based surveillance to ensure the safety of the bridge until it could be replaced. The bridge was equipped with strain gauges, accelerometers, an inclinometer, and a weather station. Data was sampled continuously at 200 Hz from 25 sensors to capture quasi-static and dynamic responses of passing trains and bridge openings.

The IoTBridge Dashboard provided full access to the data and presented statistical summaries and identification of loading events, enabling studies of specific train passages or bridge openings.

Moreover, the fatigue damage for all strain gauge locations was calculated by cycle counting through rainflow analysis and damage accumulation using the Palmgren-Miner rule. This enabled a visualisation of the accumulated damage and a prediction of the remaining service life.

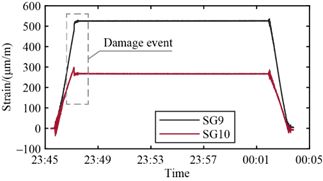

Damage detection routines were implemented to detect anomalies in the data streams from the accelerometers and strain gauges. The implemented machine learning routines made an alert of an unexpected event on Thursday, 9 March 2023. A manual inspection verified that a severe cracking event had happened in one of the truss members in the counterweight part. This detection of new damage and the severity of the damage led to the immediate closure of the bridge for traffic. After several months of further analysis, a decision was taken to replace the bridge during the summer of 2023.

Damage detection routines were implemented to detect anomalies in the data streams from the accelerometers and strain gauges. The implemented machine learning routines made an alert of an unexpected event on Thursday, 9 March 2023. A manual inspection verified that a severe cracking event had happened in one of the truss members in the counterweight part. This detection of new damage and the severity of the damage led to the immediate closure of the bridge for traffic. After several months of further analysis, a decision was taken to replace the bridge during the summer of 2023.

The project successfully demonstrated a service-life extension of a bridge with limited remaining service life. The monitoring system made it possible to maintain the bridge in service under safe conditions and issued a warning when an unexpected damage event happened.